Construction risk can generally be categorized as Rework/Defect, Safety, Loss or Unforeseeable. As it should, safety is commonly addressed on construction sites with robust safety programs, oversight and regulations due to the threat to life.

It has been suggested that safety programs cost 2.5% of project costs when construction site injuries account for 6%-9% of the total project cost.

Here we will discuss the quality assurance as it relates to rework/defects – financial risk equal to safety.

The American Society of Quality (ASQ) defines quality management as: The application of a quality management system in managing a process to achieve maximum customer satisfaction at the lowest overall cost to the organization while continuing to improve the process.

Quality management involves establishing a culture of

“doing it right the first time”

Rework – reduces workflow:

- Incomplete drawings

- Poorly defined scope of work

- Mismanagement of change orders

- Poorly written contracts

- Unknown site conditions

- Issues with subcontractors and suppliers

- Poor project management

A study conducted by Navigant Construction Forum placed the total cost of rework, including both the direct and indirect factors combined, at 9% of the total project cost – this is equal to construction site injuries. Quality assurance programs should be as robust as safety programs to address the risk.

The Construction Specification Institute (CSI) defines quality assurance during design as: The procedures for guarding against defects and elements of the design for conformance with requirements.

The CSI suggests that the goal of every design team should be to prepare “clear, concise, correct, and complete” documents.

Reasons teams fail to attain their goals:

- Lack of support for Team Culture

- Lack of proper Team Usage

- Lack of Planning

- Lack of Resources

- Lack of Clarity

- Lack of Mutual Accountability

- Lack of Effective or Shared Leadership

- Lack of focus on Creativity and Excellence

- Lack of Training

Research recommendations:

- Design firms are advised to integrate construction knowledge & contractor’s experience in the design process as an approach to improve building performance

- Changing organizational culture & getting senior management support are essential for successful implementation of constructability concept in design firms

- Barriers to constructability need to be identified & strategies for overcoming have to be planned, implemented & evaluated

- Design firms are encouraged to…facilitate the integration of…constructability concept in the design process

SOURCE: A.A.E Othman – Improving Building Performance Through Integrating Constructability in the Organization, Technology and Management in Construction – An International Journal – 3(2)2011

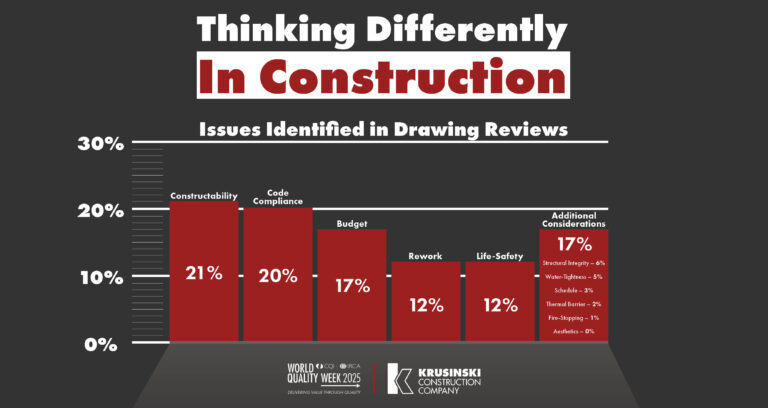

A quality assurance program should be implemented to minimize the risk of rework by aiding design teams in attaining their goals. Those overseeing the quality assurance program should orchestrate collaboration, share lessons learned, review standards, perform constructability reviews, undertake mock-ups, and be the champion of a non-traditional design process.

A non-traditional design process is more appropriate considering the complexity of today’s buildings. It is important to bring construction expertise into the design process and allow the design expertise to inform the construction process. Gone is a Design-Bid-Build approach. The construction team should be informed of the client’s goal and expectations while understanding the design intent. They will ultimately build better – armed with that information.

Macleamy’s curve. Effort spent over a project’s life cycle from (The Construction Users Roundatable, 2004). The peak for effectiveness is shifted towards the earlier design stage (shown in curve 4) in IDP compared to the conventional practice (shown in curve 3).

Having brought construction superintendents to the design development review, as part of a quality assurance program I oversaw, I can assure you it is productive and appropriate!

At minimum, that process eliminated the need to submit requests for information (RFIs). This assured more accurate bids, reduced schedule delays, and saved the design team the cost of responding.

SOURCE: Impact & Control of RFIs on Construction Projects, Navigant Construction Forum

One study shows that an average of 887 RFIs per construction project were submitted in [the] Americas (Hughes et al., 2013). That equates to, on average, $957,960 for review and response by the design team. Let’s assume the construction team is spending nearly the same identifying and preparing the RFI. There is a significant financial incentive to commit to a robust quality assurance program. We will not discuss the impact the average 9.7-day response to RFIs has on the schedule, but we can all agree time is money.

RFIs minimize rework during construction, but post-construction rework is another risk to consider. What pops up during warranty or perhaps worse yet post-occupancy. Construction defects are the basis of lawsuits that are an even bigger risk.

Common construction defects:

- Façade Leaks – often lead to mold issues

- Windows Leaks – usually related to faulty installation

- Wood Flooring Issues – usually leads to sound transmission & warpage

- Fire-Stopping Deficiencies – can contribute to loss of life

- Ventilation / Exhaust Issues – can contribute to occupant discomfort & often lead to mold issues

- Plumbing Leaks

- Inferior Substitutions

- Inadequate Warranties

The cost of construction defects was more complicated to define here with studies suggesting 4% of the total budget while others said 15%-40%. When construction defects do come up in conversation no one is happy about them! A thorough quality assurance plan can do nothing but reduce construction defects – avoiding litigation and post-construction rework.

Let’s consider the impact of rework and defects on an example project. A 100-unit senior housing community would likely have a $18M construction budget. Statistically there is a $2,300,000-$8,800,000 total risk and unfortunately, many commercial general liability policies do not provide coverage for construction defects. Both the language of the policy and the laws of the state are important in interpreting coverage. Quality assurance is intended to address this.

Robust project specific quality assurance plan can:

- Adopt a commonly accepted quality management standard like ISO 9001

- Bring construction knowledge deep into the design process

- Devise standard documentation and processes that are likely to live on a management platform such as Procore or PlanGrid assuring all partners have full access

- Institute reviews such as peer, coordination, accessibility, building code, and constructability

- Include an extensive building envelope review meeting including all trade partners and the associate technical reps for the envelope materials

- Include mock-ups, first installation reviews, and testing

- Review applicable codes, regulations, ordinances, and standards

- Establish regular pre-construction, progress, and coordination meetings

- Inform cost estimates and schedules

- Define the request for information, observation and punch list processes

- Support a scheduling process like that of the Lean Construction Institute (LCI)

Currently we are seeing larger/more sophisticated builders bring quality assurance in-house under the oversight of technically oriented professionals, often architects, with a strong background in construction. There are advantages to that approach with their ability to understand the design intent and convey that to the construction team as well as their ability to act as an in-house consultant on detailing and code issues. Multi discipline experience tends to be a benefit to an effective manager of a quality assurance program by understanding an issue from its various sides. Quality assurance often appears as a bullet point in job descriptions for project/construction managers, but it is complex problem that deserves greater attention. All that being said, there are also options to hire quality assurance consultants, like Quality Built, affording smaller builders a similar level of risk management.

Finally, a thorough quality assurance program reduces the number of RFIs, the risk of rework, and the risk of defects inherent in the construction. That program should be undertaken throughout the life of the project with the intent of it becoming standard operating procedure for all team members from architect to operator. All this equates to savings, in both time and money, as well as a on-time product with less frustration for all parties – owner, architect, engineer, builder, supplier, trade partner, operator, and user.